Semiconductor

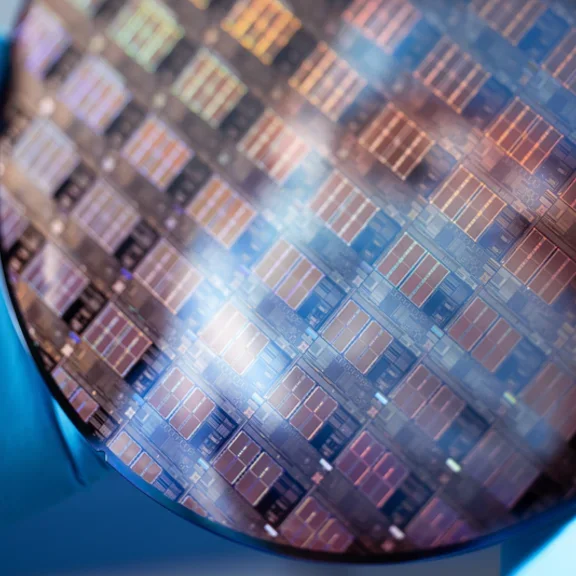

Integral to everything from processors found inside smartphones or computers to memory chips and image sensors, the use of semiconductor chips or integrated-circuits is now spreading outside the digital world.

In the world of the semiconductor industry, size always matters.

Integral to everything from processors found inside smartphones or computers to memory chips and image sensors, the use of semiconductor chips or integrated-circuits is now spreading outside the digital world. With every new application and end-user expectations for more performances come ever-greater challenges to produce smaller and more cost-efficient semiconductor chips. Manufacturers can rely on Air Liquide to meet these needs.

230 billion

#1 co-leader

3,000 Air Liquide Specialists

Growing markets for semiconductors

Semiconductor chips (also called integrated-circuits) are basically computing processors, memories, sensors, micro-controllers, power devices and other devices.

Although they are used primarily in computers, we serve more and more semiconductors manufacturers worldwide by improving the connectivity and performance of smartphones and tablets. In fact the use of chips is spreading to new areas. Just one example is the automotive industry, where integrated-circuits are replacing mechanical or fluidic systems for acceleration and braking control and enabling smart anti-collision systems. Connected smart objects or so called “Internet of Things”, are also incorporating semiconductors.

Air Liquide accompanies semiconductor manufacturers, delivering the ultra-high purity carrier gases needed to keep their manufacturing processes clean and stable over time. We also supply the specialty and advanced electronics materials (also called precursor molecules) to produce the semiconductor chips, and provide the equipment and services for the safe and optimum handling and distribution of our products.

ALOHA™ represents leadership in semiconductor deposition materials with unique expertise in Silicon, High-k, and Metals. We support customer innovation through R&D centers located in Japan, Korea, and the United States close to major innovation clusters. Each material is designed from a small scale with a target application in mind but also thought in a bigger picture of material requirements from our customers.

ALOHA™ technology leadership extends beyond chemical precursors to include packaging and delivery.

ALOHA™ technology leadership extends beyond chemical precursors to include packaging and delivery. ALOHA™ packages are engineered to fit safety and regulatory requirements while ensuring consistent delivery for each molecule. ALOHA™ canister fleet management maintains a consistent, stable supply.

Key ALOHA™ materials include ZyALD™, TSA, HCDS, and SAM.24™ that are used in critical Chemical Vapor Deposition (CVD) and Atomic Layer Deposition (ALD) applications by our customers. We continue to augment our offer with our world-class capabilities in new molecule screening, synthesis, purification, packaging, chemical analysis, and applications development.

Some new product offerings include precursors for deposition of metals such as Ruthenium, Tungsten, and Cobalt which are used in the leading edge semiconductor devices.

Voltaix™ products are used to deposit thin films via Chemical Vapor Deposition (CVD) and Atomic Layer Deposition (ALD). Voltaix™ products are critical to channel engineering and advanced memory structures. These structures enable computer chips with lower power consumption and higher memory density, which enhance our personal mobility and connectivity.

Key Voltaix™ materials include disilane, germane and diborane used in the manufacture of logic, memory, and photovoltaic devices. These products are developed in collaboration with leading researchers, enabling frame-breaking innovations in thin film properties, and thin film processing.

Balazs™ provides accurate, timely analytical services to the semiconductor, disk drive, pharmaceutical, power and other industries. We analyze ultra pure water, source water and chemicals; equipment and components; thin films and bare wafers; wet stations; and anything in the cleanroom including gases and the air. We test for trace level metals, ions, particles and organics. Balazs™ is committed to absolute quality control of processes and products.